Types of Asphalt Mix and Their Applications

Categories

Table of Contents

- What Factors Determine Different Types of Asphalt Mixes?

- Types of Asphalt Aggregate Structure

- Types of Asphalt Aggregate Size

- The Best Asphalt Mixes for Different Applications

With asphalt being such a durable and dependable material, a common assumption when trying to create high-quality roadways is, “Asphalt does the work.”

Well…you know what they say about assuming.

Asphalt is certainly reliable, but only if you pair the right mix type (or types) with the right application. We’re breaking down different asphalt mix types and their corresponding applications so you can select the most appropriate asphalt mix types for your project.

[ video here ]

What Factors Determine Different Types of Asphalt Mixes?

The main component that controls an asphalt mix type is its aggregate structure, which refers to how aggregates, like rocks and mineral filler, are arranged within a mix.

Asphalt aggregate size refers to the sizes of the rocks, mineral filler and other materials distributed throughout an asphalt mix. Aggregate size doesn’t necessarily distinguish one mix type from another, since you can have different aggregate sizes paired with the same aggregate structure.

Another critical component within an asphalt mix is its binder, or the liquid that holds a mix’s aggregates together. Again, different binders can result in the same mix type if the mix contains the same aggregate structure. We’ll dive more deeply into binders in a future blog.

Together, the combination of different aggregate structures, aggregate sizes and binders can result in a variety of different types of asphalt mixes.

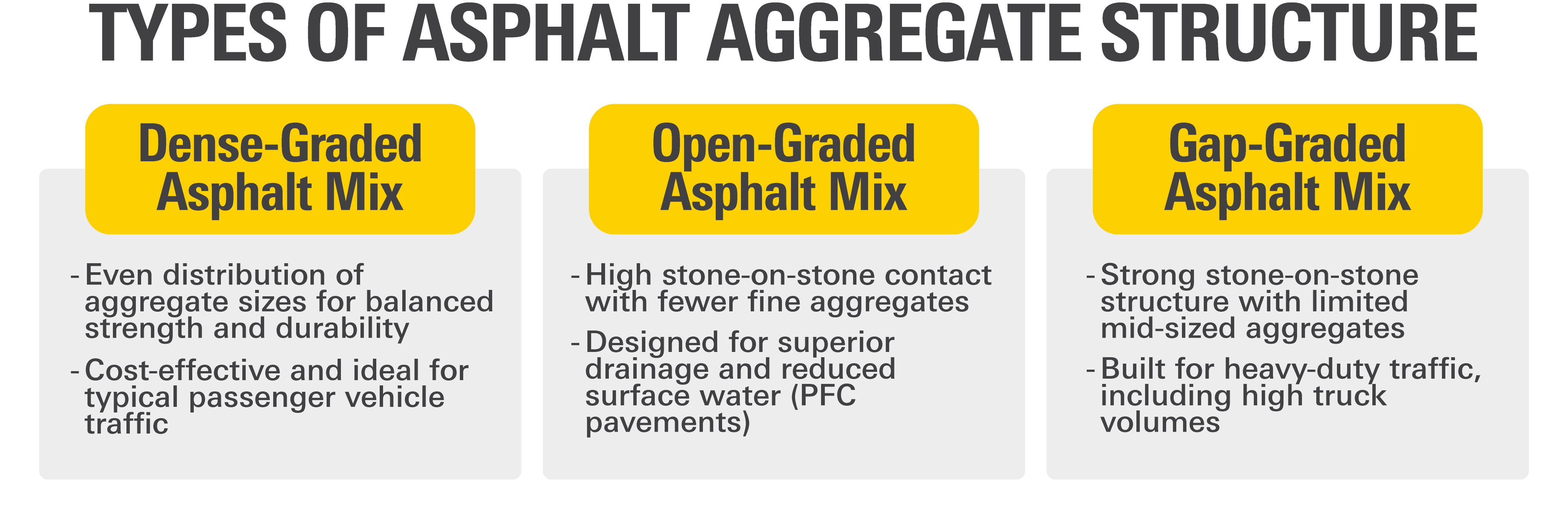

Types of Asphalt Aggregate Structure

The three main types of aggregate structure in asphalt mixes are dense-graded, open-graded and gap-graded.

Dense-Graded Asphalt Mix

Dense-graded asphalt mixtures are the bread and butter of asphalt mix aggregate structures. Think of it as a Goldilocks mix: it’s not too heavy-duty to support trucks, and it’s not super thin to take care of surface defects. Dense-graded asphalt mix has a fairly even distribution of aggregate sizes throughout the structure and is used for typical traffic.

Open-Graded Asphalt Mix

Open-graded asphalt mixtures have more stone-on-stone contact. These are excellent for drainage and contain more binder because there are fewer small rocks in the mixture. Permeable friction course (PFC) pavements fall under this category.

Gap-Graded Asphalt Mix

Gap-graded asphalt mixtures aren’t as open as open-graded asphalt mixtures, but they’re typically used on heavy-duty pavement structures and are also effective at drainage with lots of stone-on-stone contact. Stone matrix asphalt (SMA) falls under this category.

Types of Asphalt Aggregate Size

Types B, C, D and F are the most common asphalt aggregate sizes you’ll find within Texas dense-graded asphalt mixes. The main difference between each type is the top size of the aggregates in the mix.

Type B

- One of the most common asphalt aggregate sizes we see (along with Type D)

- Less expensive than Type D

- Tends to serve as either a subsurface or intermediate course

- Can be found in industrial areas with slow traffic and frequent turns off of main roads into driveways of commercial facilities

Type C

- Relatively common in Texas

- Can serve as a cost-effective foundational layer or as an intermediate layer for low to moderate traffic levels

- Like Type B, it can be found in industrial areas with slow traffic and frequent turns off of main roads into driveways of commercial facilities

Type D

- One of the most common asphalt aggregate sizes we see (along with Type B)

- More expensive than Type B

- Tends to serve as the top layer of asphalt pavements

- Provides a smooth, weather-resistant surface for residential streets and driveways, parking lots and more

Type F

- A more specialized asphalt mix used for certain surface applications

- An extremely fine mix with a small top size

- Provides a smooth, quiet and aesthetically pleasing finish on streets in subdivisions

The Best Asphalt Mixes for Different Applications

When determining which asphalt mix or combination of mixes is right for your project, you should ask yourself these three questions:

- What kind of vehicles are going to be driving on this roadway?

- What percentage of the traffic will be trucks?

- What will the traffic’s behavior be like? In other words, will vehicles be traveling quickly or slowly? Will there be lots of starting and stopping? Will there be lots of turning?

Residential Streets

For residential streets or slightly busier streets with passenger car traffic, you’ll want to opt for a dense-graded mix.

Dense-graded mixes are cost-effective and smooth without compromising the pavement’s ability to support traffic. If you see an asphalt-paved neighborhood, there’s a good chance that you’re looking at a dense-graded mix.

Industrial Areas

If you’re building a data center, a Costco, or any facility in between where there will be a lot of truck traffic, you’ll want a more rugged mix that can support vehicles carrying large loads.

Say you have 1,000 vehicles passing through a construction zone per day. If only 50 of those vehicles are trucks and the rest are cars, you’d be safe with a dense-graded mix. However, if 400 of those vehicles are tractor-trailers bringing goods to and from a distribution center, you’ll want a more durable mix, like a gap-graded mix.

Drainage Areas

For drainage areas located on high-speed roadways, a permeable friction course (PFC) pavement, or an open-graded mix, is usually a good bet. If there are frequent instances of skidding, standing water or accidents on a certain stretch of road when it rains, PFC pavements can help drain that water and create a safer roadway.

However, if a roadway has a lower speed limit, you may want to consider other asphalt mix types. When traffic is moving slowly on a PFC pavement, water doesn’t flow out as freely and pavements can get clogged.

Downtown Streets

Downtown streets are characterized by abrupt starting and stopping on short blocks and at intersections. They’re a special case, and choosing the best asphalt mix for them isn’t a “one-size-fits-all” scenario, but that’s often what happens.

Many downtown areas use the same asphalt mix across the board, despite frequent speed limit changes and the wide variety of traffic they see.

If vehicles go from traveling quickly to reducing speed and turning through an intersection, all on the same type of asphalt mix, the weight of traffic over time in said intersection can lead to shoving and other kinds of distress.

In other words, a mix type that works well on a 45-mile-per-hour road may perform terribly in an intersection with constant slow-moving traffic.

Do you need help choosing the best asphalt mix or mixes for your project? Call us at (512) 312-5043 to schedule a complimentary consultation, and we’ll be happy to sit down with you to walk through your project together. For more asphalt pavement industry insights, subscribe to our YouTube channel and tune into our newest podcast, Road Maps With Sam and Larry.